Dock leveler seals and shelters

Dock leveler

Product overview

In the field of logistics, our dock leveler can realize fast and safe loading and unloading process. The dock leveler can balance the height difference between the platform ground and the dock of different transport vehicles. Whether it is a flatbed truck or a container truck, the dock leveler can meet the requirements. The sturdy steel structure design and high-quality materials provide a reliable choice for all loading and unloading yards.

Product advantages

After the transport vehicle approaches, the platform, the door opens, keep pressing the control button, the platform rises to the highest position, the lip plate automatically opens and releases the control button, the platform falls down until the lip plate overlaps with the transport vehicle compartment plate, then you can proceed with the loading and unloading. After loading the unloading, keep pressing the control button to reset the platform.

Product features

- 400mm long and 16mm thickness plates create a horizontal non-slip sink arch

- Bridge and strengthened tongue plate, the transition is smoother

- Full welding and stress relief process

- Arch bridge or reinforced rear transition plate

- Particularly sturdy and reliable canned heavy bridge hinge

- Integrated electro-hydraulic unit

- Protective umbrella safety support rod

- The seam between the countertop and the platform is sealed by the whole brush strip – A(width) 1800-2000mm; B(length) 2000-4000mm; C(height) 600/500mm

Different dock leveler options

The hyduarlic dock leveler ensures stable and safety operation.Hydaulic pump, conduit and oil storage box are mounted on the bottom of the working table. Reliable valve is in the range of 75mm. Operation accessories increase operating security and convenience. Low maintenance requirements.

Advanced low pressure lifting system complete the gas tower lifting, ensure running stable and safe. Cylindrical gas tower can resist wear and tear, long service life. The motor and the blower are installed above ground. All the electrical components, cables and accessories meet the UL standard. Low maintenance requirements.

Unique balance system ensures the smooth process of unloading. Heavy load slope controls the device. Manual working under the condition of power failure. Maintenance requirements are relatively high compare with another two options.

Technical parameters

| Width | 1800mm | 2000mm | 1800mm | 2000mm | 1800mm | 2000mm | 1800mm | 2000mm | 1800mm |

|---|---|---|---|---|---|---|---|---|---|

| LENGTH | 2000mm | 2000mm | 2500mm | 2500mm | 3000mm | 3000mm | 3500mm | 3500mm | 4000mm |

| HEIGHT | 600/500mm | 600/500mm | 600/500mm | 600/500mm | 600/500mm | 600/500mm | 600/500mm | 600/500mm | 600/500mm |

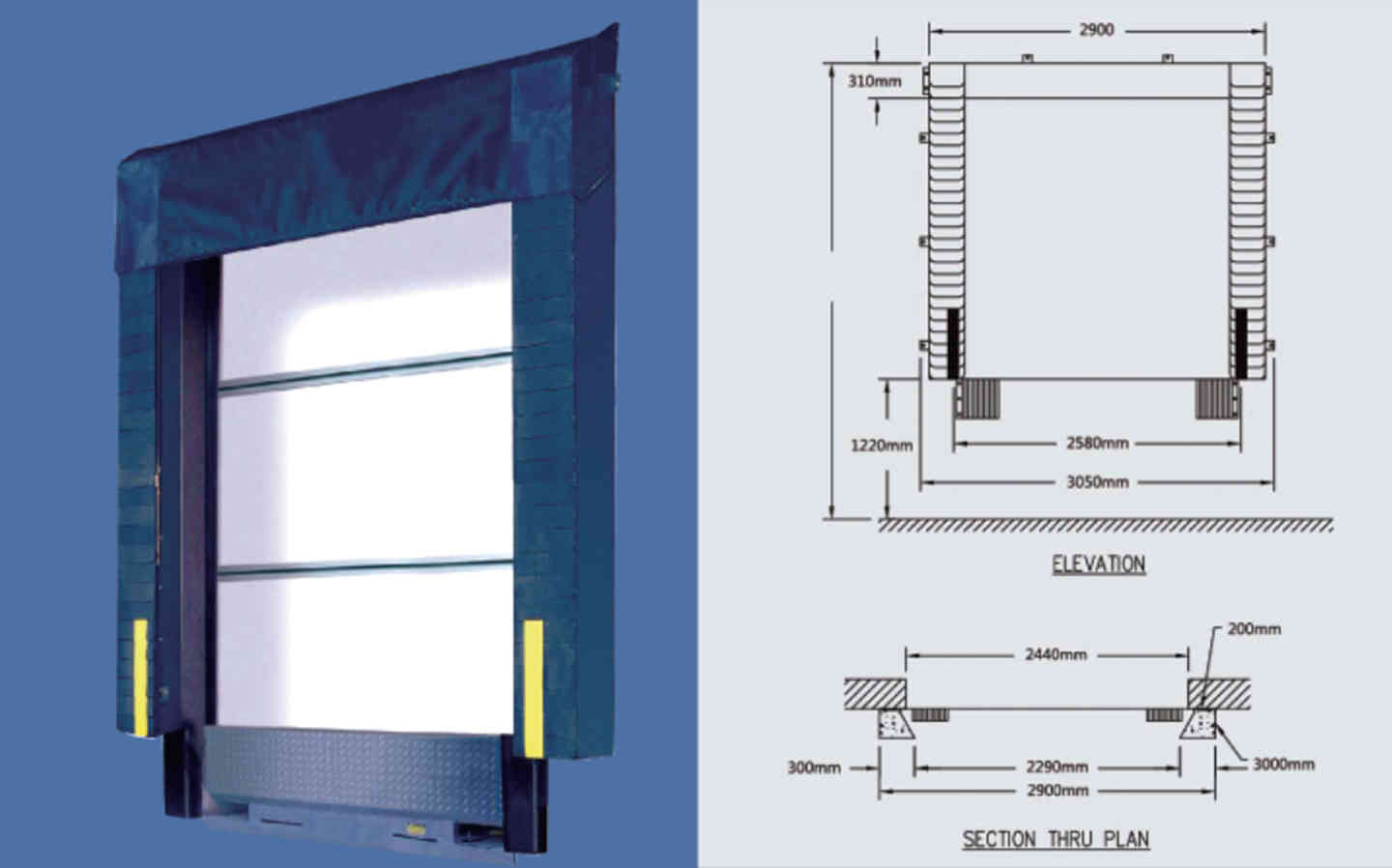

Dock shelter

Internal filling material & External coating

- Inner filling material is polyester sponge

- Foaming density: 33KG/ per square meter

- Closed cell foaming to realize the good sound-proof performance

- Follow GB10010 standard self-extinguishing flame retardant

- Good acid/alkali/oil resistance performance

External coating materials

- Materials are 100% poluest and 100% PES

- Thickness is 0.8mm

- Special surface treatment, with good cleanliness performance

- Follow German DIN75200 fireproofing standard

- Applied temp: -30°C~+70°C

- Good acid/alkali/oil resistance performance

Steel frame & sealing plate structure

- The main body franme is made by T60 status aluminium alloy, with surface oxidation treatment. The crssing arrow type is made by qualified carbon steel with zinc metalizing treatment. The spring buffering structure is made by zinc metalized spring.

- The front curtain is made by 3mm reinforced double fiber coating. The side curtain is made by 0.8mm coating. We do the special surface treatment with good cleanliness performance, conform to German DIN 75200 or China GB 10010 fireproofing standard.