Automatic folding doors

Product overview

Our automatic folding door features the automatic operation and rapid opening from closure to full opening, it also can be manual operated in case of power failure easily. Our automatic folding door will bring you the fastest running speed and security at any time. The European standard production process has been used in folding doors, and the frame is invisible. Also, coarctation design is used between surface panel and frame, without welding.

The high density polyurethane foam whose density exceeds 50kg/m3 is used for the whole door. It can not only enhance the tightness between surface and implicit frame, but also beautify the appearance to a large extent.

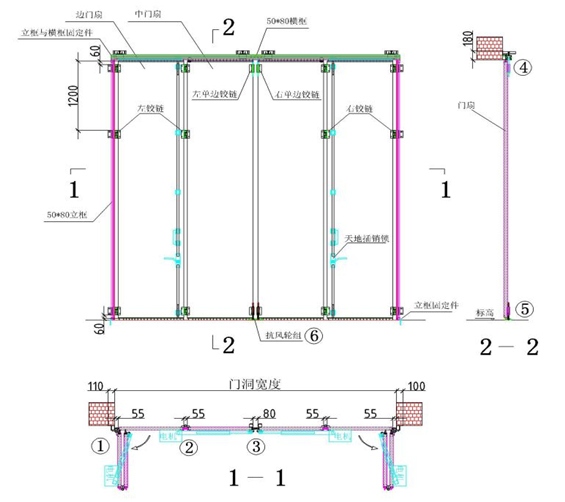

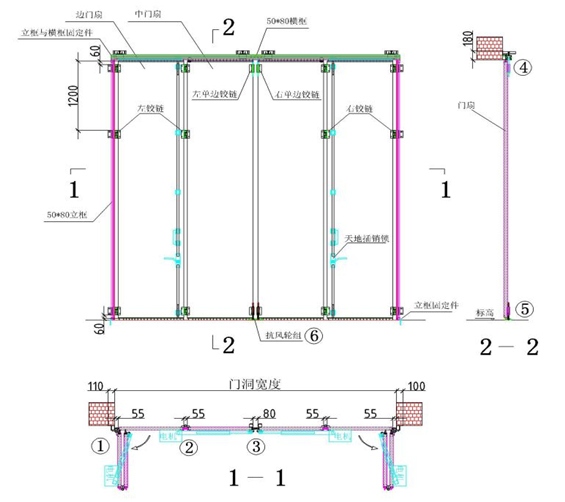

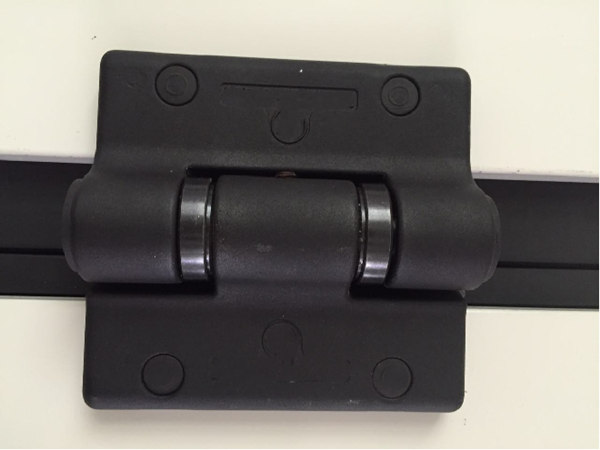

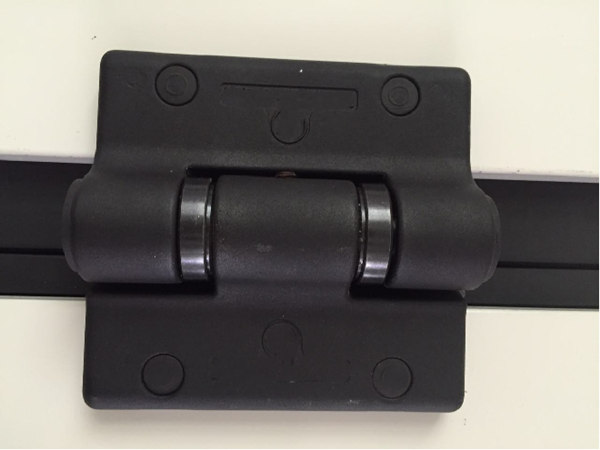

The connecting hinge adopts casting aluminium and plane thrust bearing, reduced the friction caused by resistance.

Frame adopts the professional aluminium alloy strengthening design to make installation much more convenient, solid and improve the degree of beauty. In the assembly, we use embedded pull rivet nut, prevent the screw loose.

Product application

Rapid fireproof folding door

High speed folding door for fireproof, high-speed opening and normal speed opening optional. The fastest opening speed can be 90° at 7 seconds, normal speed can reach 90° between 16-26 seconds (differ from door width).

Commerical folding door

With modern and futurist appearance, our commerical folding door is a flexible door, U value is 1.1W/M2°K, noise in laboratory can be reduced in 55 dB, which is suitable for disabled people access.

Subway folding door

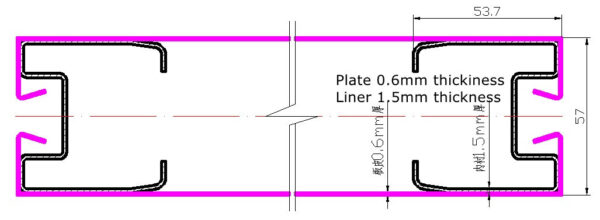

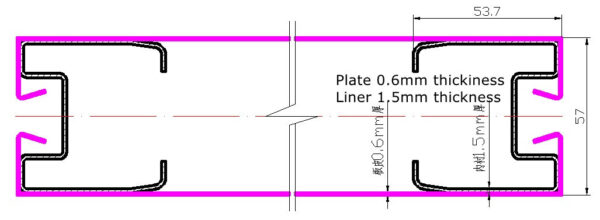

Thickness of door panel is 57mm; Surface material uses aluminium zinc plate or aluminium plate, the plate thickness is 0.6mm-1.2mm; Open mode: manual, automatic, infrared ray and so on; Foaming density exceeds 59KG/m3; Can reserve high voltage wire insulation; Material of frame: Steel or aluminium; Width adaption: Steel≤5060mm, aluminium≤6000mm

Product appearance

- The external panel color is white & gray, and special colors are customized;

- The color can be customized according to RAL color cards;

- Surface anodized / galvanized / painted surface treatment is carried out on all hardware;

- Surface spraying treatment is carried out on aluminium alloy accessories

Product features

- Hidden frame design: The frame of door is made of cold-rolled galvanized steel, and designed with U-shape concave and convex grooves molded by special rolling machine. It is covered with 0.6mm to 1.2mm of aluminium plating zinc plate or aluminium alloy plates on both sides, and foamed overall.

- It has higher strength, the thickness (57mm & 77mm) is optional.

- It has multi-section structure doors, when the door doesn’t need to be completely opened, a part of the door will open to reduce the open & close time, and heat loss.

- The top of the door is sealed with high density double-layer brush. The door frames and each door panel are sealed with EPDM.

- The top rail is made by 4mm thickness steel plates, and mounted directly on the side wall or fixed on the eaves. The thickness should not be less than 4mm.

- The bottom water deflector is made of 2mm thickness aluminium alloy guide slots with a small angle of waterproof slope (or more special design configuration). The bottom water deflector is configured as standard when there are more than 3 sections / panels in a single door, and it is optional when less than 2 sections / panels.

- Door and hinge are connected by embedded pull rivet nuts, the hardware for connecting the door is embedded rivet nuts.

- The top rail is made of 50x50x3mm steel or 5mm thickness aluminium alloy, the top rail with one-sided four flods is made of 4mm galvanized steel molding rails.

- Hanging wheels are made of sealed bearings and PA66 nylon, four wheels can increase the strength and make the door move smoothly.

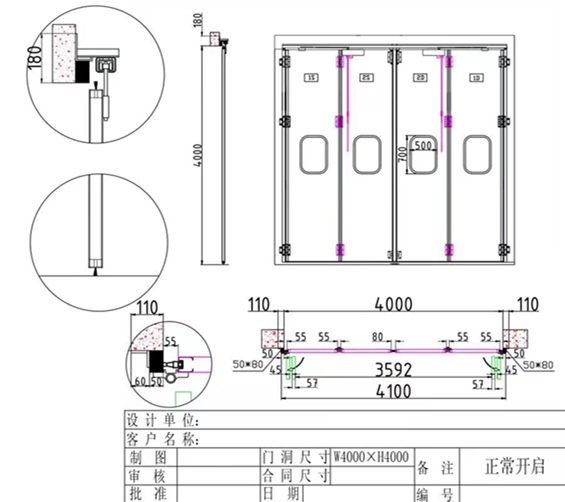

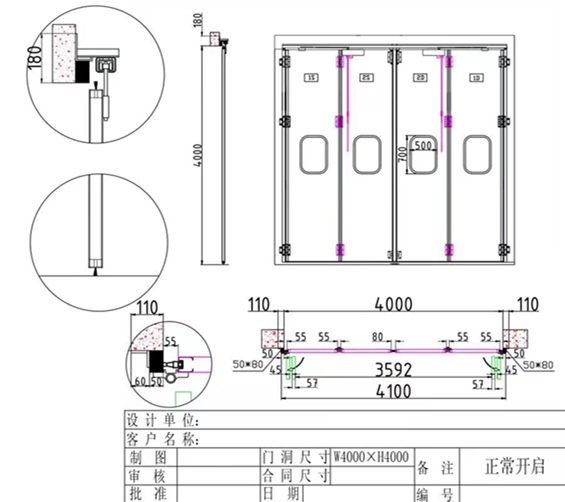

- Configuration range: Standard width of single-section can be 650mm to 1200mm, the maximum width of single section is 1500mm, the thickness of the door panel is 57mm or 77mm optional. For the 77mm panel, it is appropriate door height of 8000mm, and the maximum height of a single door panel is 13000mm; For the 57mm panel, it is appropriate door height less than 8000mm.

Safety lock

- A latch and a handle fixed on a manual folding door panel.

- Electric gate motor automatic lock in the closed position; with a clutch device, it allows to open the door manually.

Optional

- Single or double-sided panels and all external hinge facilities can choose standard Ral colors for polyester powder coating.

- Drive part uses a low-noise fast motor (opening time can be set according to the motor).

- Double visible acrylic window or tempered laminated window.

- Wicket can choose escape lock.

Different opening methods

- Remote control to open

- Wipe card to open

- Induction coil / ground loop to open

- Infrared induction to open

- Radar to open

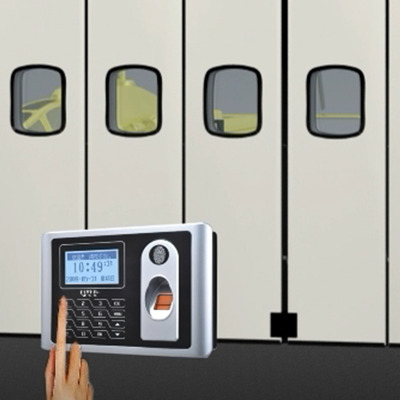

Infrared induction

Fingerprint

Control panel

Induction coil

Radar

Remote

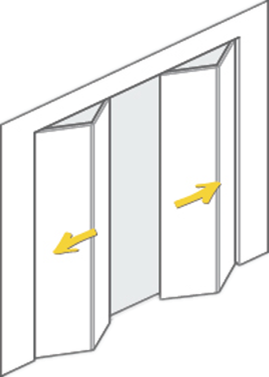

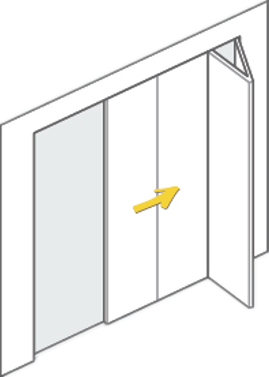

Opening style

Bidirectional folded open

One-way folded open

24V folding door opener optional

- LED screen (multiple language), easy to install and test

- Electronic limit switch, the open & close limitation is precise and stable

- Can connect the external manual release

Technical parameter:

- Power supply: 230±10%, 50-60Hz

- Motor working voltage: 24V

- Power: 40W

- Maximum torque: 300Nm

- Mximum door width (single panel): 2.5m(200kg)/2m(250kg)

- Limitation: Electron

- Opening time: 15 seconds

- Speed reduction: Yes

- Auto-reverse: Intelligent torque detect system

- Self-locking: Mechanic

- Manual release: Release the torque

- Operating frequency: Low intensive use

- Operating ambient temperature: -20°C~+50°C

- Protection level: IP44/IP55

- Weight: 16kg

Different folding door types

Automatic type

Manual type

Our strength

- Door panel

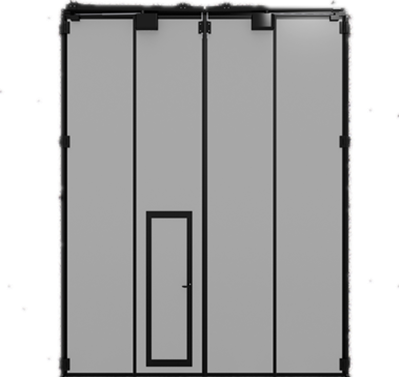

Our folding door complies to European standard, the door panel is made of double-sided 0.8mm BAO steel color-coated plate, and the middle is filled with 50kg of polyurethane per cube meter. The integration process adopts 1.5mm galvanized steel plate to form a built-in hidden structual frame design. The force combines the three materials into one and the strength is improved. Zero welding joint on the surface, the weight per square is up to 24kg, which not only ensures the wind resistance strength, but alos protects the surface of the door panel from rainwater corrosion. In addition, a small pedestrian door can be opened on the common passage door panel, which is more convenient.

- Hardware

All load-bearing hinges of the folding door are made of precision alloy casting, each hinge is installed with a compression bearing, and a stable groove is customized at the installation of each load-bearing hinge and the door panel. Each single load-bearing hinge or suspension wheel bears 600kg, and increases door panel sealing device. The track thickness is 3mm, adopt doublt tracks system, the rollers are made by ABS materail.

Our professionalism

Our team works in this industry with many years’ experience, from the design, manufacture, package, delivery, installation and commissioning, maintenance after-sale service, we provide all-sided supports for our customers at every link, particularly, our technicans can design the suitable folding door based on the customers’ practical demand to save the cost, and provide our customers the effective training to help them operate and maintain the doors properly.